© Copyright 1976-2017 Shenzhen Vodno Technology Co., Ltd All rights reserved. Powered by iwonder.cn

The sole battery that could be used for portable electronics, including wireless communications and mobile computers, was nickel-cadmium for a very long time. Lithium-ion and nickel-metal-hydride were developed.

Early in the 1990s, businesses competed fiercely for customers' favor. Currently, lithium-ion is the most promising and rapidly expanding battery chemistry.

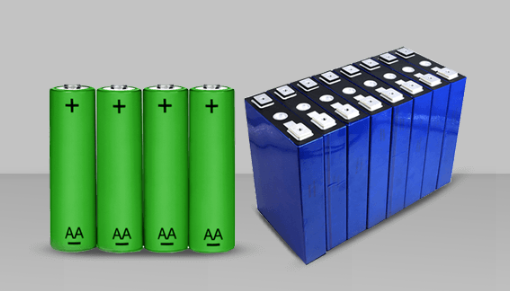

This article will go into greater details about the differences between lithium-ion batteries and lithium polymer batteries.

Battery maintenance is minimal with lithium-ion, which is something that most other chemistries cannot say. There is no memory, and the battery doesn't need to cycle on a timetable.

Furthermore, lithium-ion has a self-discharge that is less than half that of nickel-cadmium, making it an excellent choice for contemporary fuel gauge applications. When discarded, lithium-ion cells don't cause much damage.

Lithium-ion has disadvantages despite overall benefits. It is delicate and needs a protection circuit to continue operating safely.

The protection circuit, which is incorporated into each pack, controls the peak voltage that each cell can reach while charging and prevents the cell voltage from falling too low during discharge.

To avoid temperature extremes, the cell temperature is also tracked. Most packs have a maximum charge and discharge current restriction of between 1C and 2C. By taking these steps, it is almost impossible for metallic lithium plating to result from an overcharge.

The type of electrolyte employed by the lithium-polymer battery system sets it apart from traditional battery systems. The original, 1970s-era design makes use of a dry solid polymer electrolyte.

This electrolyte, which resembles a plastic-like layer but permits ions to exchange, does not transmit electricity (electrically charged atoms or groups of atoms). The conventional porous separator that is soaked in electrolyte is replaced by the polymer the electrolyte.

The dry polymer design offers simplifications in terms of thin-profile geometry, safety, toughness, and manufacture.

Designing equipment with a cell thickness as thin as one millimeter (0.039 inches) is left to the designers' ingenuity in terms of form, shape, and size.

The adoption of the lithium-ion polymer has not been as rapid as some analysts had predicted. Its advantages over alternative technologies and affordable manufacturing have not been realized.

The capacity is not increased it is somewhat lower than that of a lithium-ion battery that is used more frequently. In wafer-thin geometries, such as batteries for credit card readers and other similar applications, lithium-ion polymer finds its market niche.

Lithium-ion batteries age more slowly when kept in a cool environment (and other chemistries).

Manufacturers advise 15°C (59°F) storage temperatures. The battery should also be half-charged while being stored. Manufacturer suggestions call for a 40% fee.

DO you have questions and concerns about lithium ion battery cell? If yes, then feel free to inquire with us about your lithium-ion battery cell and we’ll be glad to help you out.